Beschreibung

Suitable to: for the production of glued boards according to different quality classes.

|

Line consisting of: |

|

|

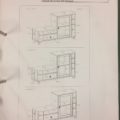

1. Feeding mechanism to Hydromat machine – tiling of boards from the pallet to the slats. |

TS Bison System – length of the boards for cutting 500 – 2500 mm – thickness of cutting boards 19 – 75 (100) mm – width of boards for cutting 50 – 250 mm – delivery to the planer max. 60 pcs / min (5 layers per minute) – max length tolerance + -5mm – engine power 12,5 kW – Siemens electronic programming – the control cabinet is standing upright – machine length 3900mm Dimensions of the pallet / package of platters. – package height max 1800 mm – width / depth of package max 1200 mm |

|

2. Weing Hydromat 23E – planer, cutter |

Feed rate 60m / min |

|

3. The receiver for the planer separating the lamellas. |

Transfer of single slit lamella to the scanner. |

|

4. Wood Scanner LuxScan (Weinig Group) |

Dimensions of scanned workpieces: |

|

5. Sorting lamella by different quality classes |

Capacity of 120 lams / min = 120m / min with 1m length lamination. |

|

6. Stacking / stacking on finished pallets. |

OPTI Stacker – 5 units of independent stackers for pallets in different quality classes. |

|

Control: |

Separate control cabinets with Siemens programmer |

|

Space requirements: |

approx. 50m x 7m (without planer as the second member 30m x 7m) |

|

|

|

(Subject to errors, technical modifications and prior sale)